Why it is no longer an efficiency program, but a value and growth imperative

For many CEOs, Lean transformation still carries an outdated image: factory floors, time-and-motion studies, and cost cutting. That perception is no longer just incomplete—it is strategically dangerous.

Today, Lean is one of the few enterprise-wide systems proven to simultaneously improve cost, speed, quality, and employee engagement—at scale. In an environment defined by margin pressure, talent shortages, and AI-driven disruption, Lean has quietly re-emerged as a core operating advantage.

This article simplifies Lean transformation for CEOs—what it truly is, where it creates value, and how progress should be measured using clear, executive-level metrics.

What Lean Really Means Today (and What It Doesn’t)

At its core, Lean is not about working harder—it is about removing friction from value creation.

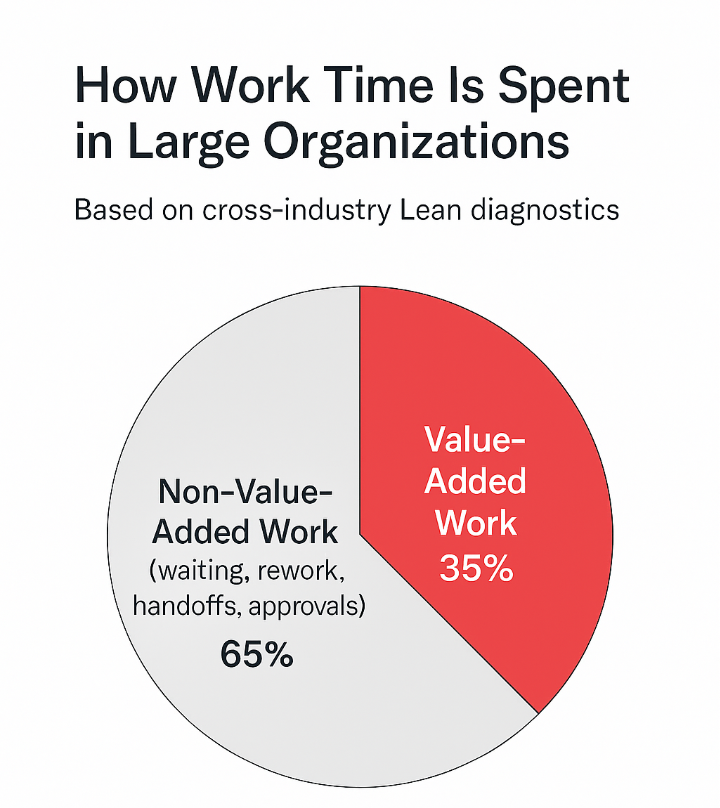

Across industries, diagnostics consistently show that:

- 30–50% of end-to-end process time is non–value adding

- 20–40% of operating costs are tied to rework, waiting, handoffs, and complexity

- 60–70% of employee effort in large organizations is absorbed by coordination rather than execution

Lean systematically identifies and eliminates this waste.

Equally important, Lean is not:

- A cost-reduction exercise in isolation

- A toolbox of techniques applied sporadically

- A one-time transformation program

Modern Lean is an enterprise operating system focused on flow, problem-solving, and accountability.

Why Lean Transformations Fail

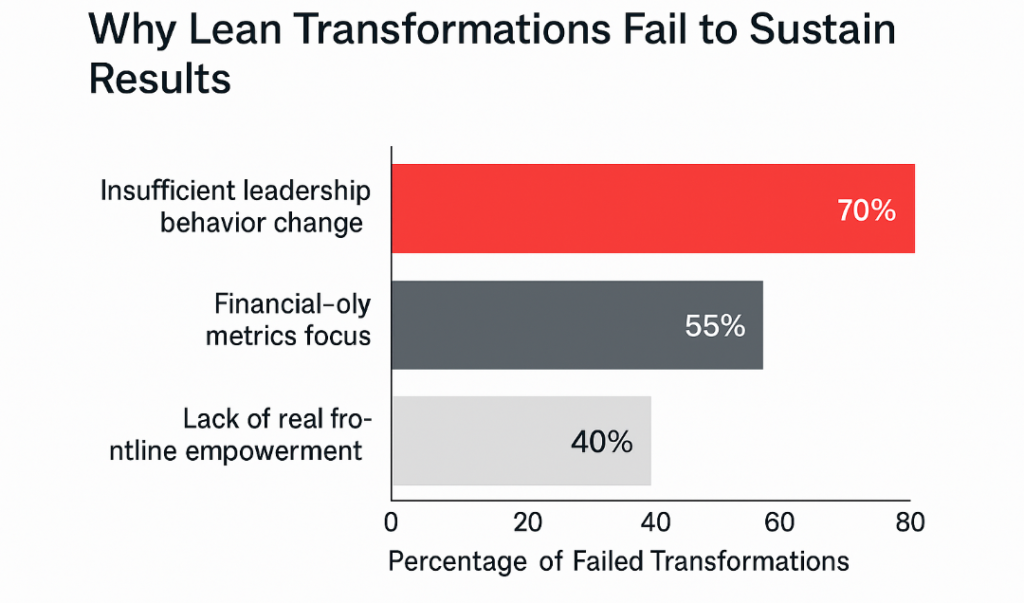

Despite decades of proven results, fewer than 25% of Lean transformations sustain their gains beyond three years.

Failure patterns are remarkably consistent:

- 70% fail due to insufficient leadership behavior change

- 55% stall because success is measured only through financial KPIs

- 40% collapse when frontline empowerment exists in theory but not in practice

Lean fails not because the methodology is flawed, but because it is treated as an operations initiative rather than a CEO-led agenda.

Where Lean Creates Enterprise Value

When executed with discipline, Lean creates value across four dimensions that matter most to CEOs.

Financial Performance

Organizations that sustain Lean typically achieve:

- 5–10% EBITDA uplift within 18–24 months

- 15–25% reduction in controllable operating costs

- 20–40% working capital release through inventory and cycle-time compression

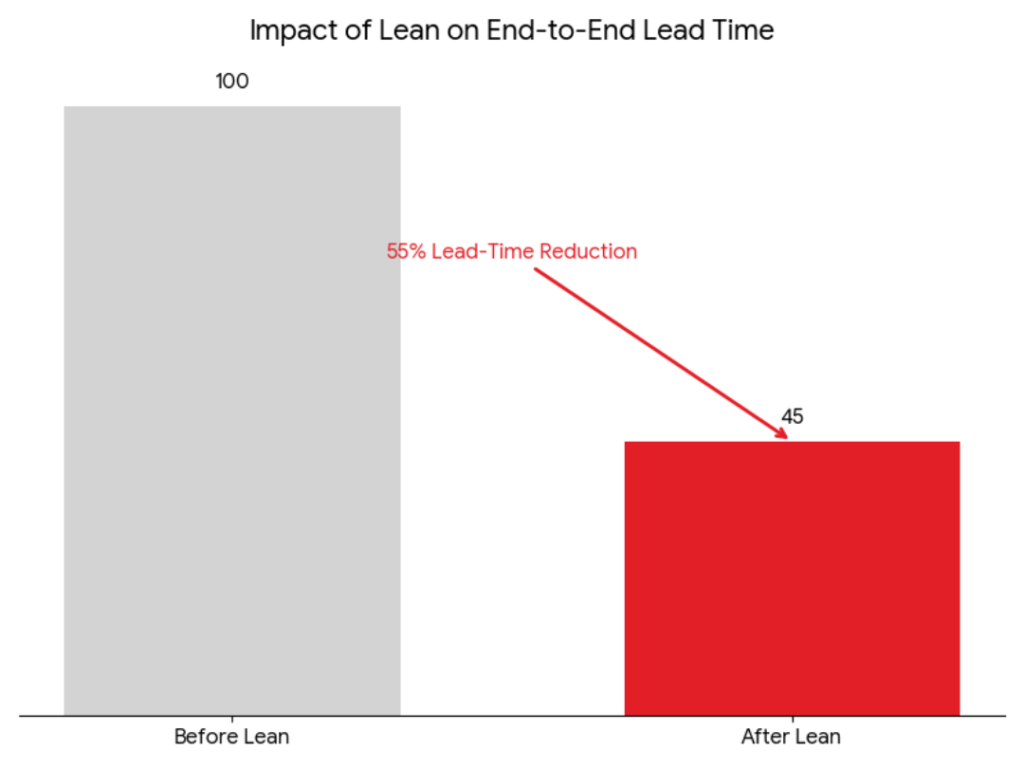

Speed and Responsiveness

Lean dramatically reduces execution latency:

- 30–60% reduction in order-to-delivery lead times

- 40–70% faster issue resolution

- 2–3x throughput improvement without increasing headcount

Speed becomes a structural advantage rather than a situational one.

Quality and Customer Experience

Lean-led organizations consistently report:

- 25–50% reduction in defects and errors

- 20–30 point improvement in Net Promoter Score over 12–18 months

- 50%+ reduction in customer complaints linked to process failures

People and Capability

Contrary to common misconceptions, Lean strengthens engagement:

- 15–25% improvement in employee engagement scores

- 2–4x increase in implemented frontline ideas

- 30–50% reduction in management escalations

Lean replaces firefighting cultures with ownership-driven execution.

Lean and AI: A Force Multiplier, Not a Choice

Lean and AI reinforce each other.

Transformation data shows that:

- ~70% of AI initiatives fail to scale due to unstable or fragmented processes

- Lean-first organizations achieve 1.5–2x higher ROI from automation and AI

- Process standardization improves AI accuracy and reliability by 20–40%

Lean provides the structured workflows that allow AI to deliver sustained value.

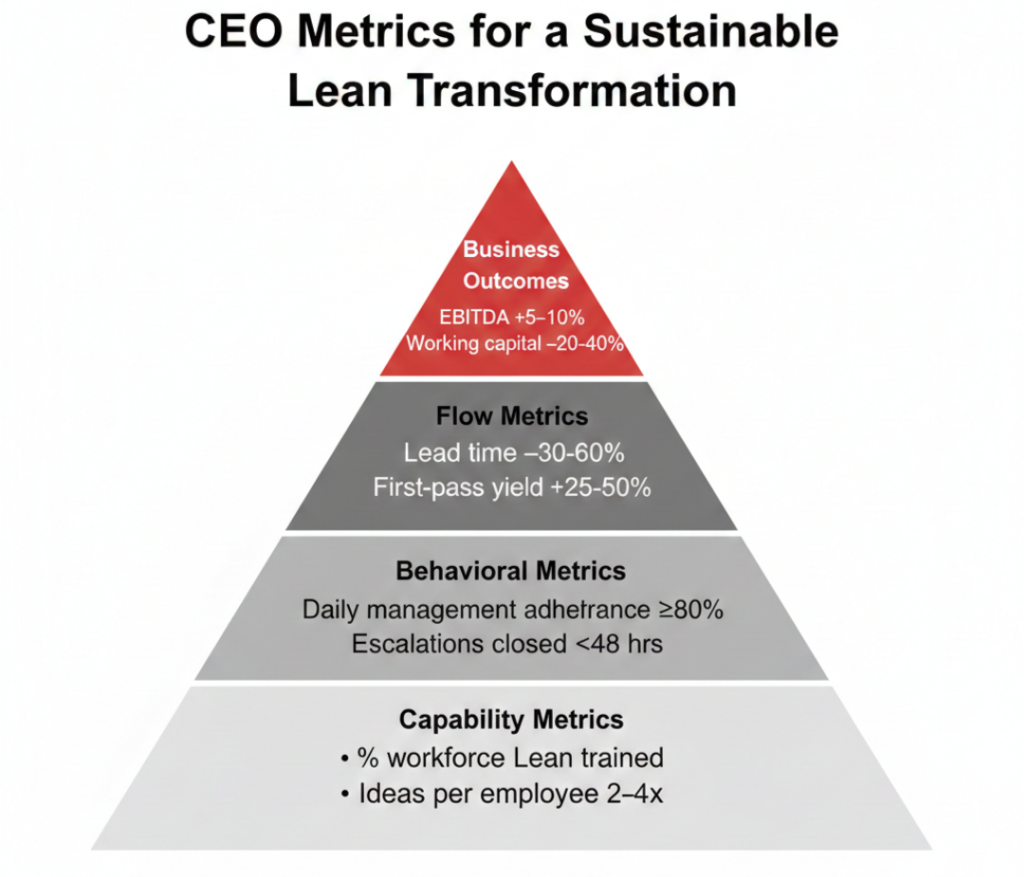

What CEOs Should Measure

High-performing Lean transformations track four interconnected layers of metrics:

- Business Outcomes

EBITDA, revenue per employee, working capital days

- Flow Metrics

End-to-end cycle time, first-pass yield, on-time delivery

- Behavioral Metrics

Daily management adherence, leader standard work completion, escalation closure rates

- Capability Metrics

Workforce Lean coverage, ideas implemented per employee, coaching hours per leader

This balance ensures that financial outcomes are driven by leading indicators—not lagging corrections.

The CEO’s Role: Three Non-Negotiables

Across successful transformations, CEOs consistently do three things:

- Spend 20–30% of transformation time at the frontline, not in steering committees

- Shift performance conversations from financial outcomes to flow and problem-solving metrics

- Personally role-model structured problem solving, asking “Where did the process fail?”

Lean succeeds only when leadership behavior changes first.

The Bottom Line

Lean transformation is no longer about efficiency—it is about building an organization that compounds value over time.

In an era of AI agents, margin pressure, and execution complexity, Lean remains one of the few proven systems that reliably converts strategy into results—every day.

For CEOs, the question is no longer whether to pursue Lean, but how quickly it can be embedded as the organization’s operating system.

Posted by the Research Team at Ved Consulting.

Connect with us on LinkedIn: https://www.linkedin.com/company/vedconsulting/